Manufacturer, Supplier, Installer of Quality Property Improvement Solutions

Features & Benefits

Energy Efficiency

At World Group, protecting your property against heat loss is one of our primary aims, the experience gained working to the highest standards and specifications since our etablishment in 1981 have helped us fully understand what it takes to safeguard your property against unwanted heat loss.

What is Energy Efficiency?

All properties lose heat through their windows, but using WORLD GROUP energy-efficient glazing keeps your home warmer and as well as reducing your energy bills. That might mean double or triple glazing being installed, or in some circumstances secondary glazing.

What are the benefits of Energy Efficient Glazing?

- Lower energy bills. In the average semi detatched house, with 'Energy Efficient' windows the bills could reduce by, on average, between £90-£120.

- A smaller carbon footprint. Through using recycled materials and utilisting old materials recycled into reinforcing we use.

- A more comfortable home: energy-efficient glazing reduces heat loss through windows and means fewer draughts and cold spots.

To get a better idea of how much you could save by replacing your windows, use the Energy Saving Calculator on the Glass and Glazing Federation's website. It may confuse you slightly with the window specific terms, but feel free to give us a call and we'll help you with the process.

How does it work?

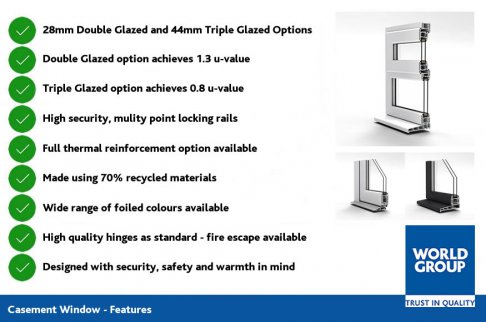

Double-glazed windows have two panes of glass with a gap between them, as standard it's now a 20mm 'spacer bar', to create an insulating barrier that keeps heat in. Nowadays, we're using 'warm edge' spacer bars to help prevent heat transfer to the outer pane. The cavity is filled with argon gas as standard by WORLD GROUP. Triple-glazed windows have three sheets of glass, and means that triple glazed windows can offer enhanced performance over double-glazed windows: to choose the most energy-efficient windows most people look for the BFRC rating. This will be anything from A to G. Our preferred measurement of energy efficiency is U-Value's - the measurement of heat loss. Building standards stipulate that we must achieve a minimum U-Value of 1.6, with a lower U-Value representing lower heat loss, making it a more energy efficient option. A standard WORLD GROUP double glazed window can achieve a U-Value of 1.3. In comparison a standard WORLD GROUP triple glazed window can achieve a U-Value of 0.8! That's showing us that triple glazed windows are upto 40% more efficient than the double glazed equivalent.

Still confused?

If you'd like more information, or have any questions we'd love to hear from you on 01228 599777 or by using the online contact form!

Is it just glass that makes a difference?

No.

There are other factors in creating an energy efficient window. The reinforcing used in the window frame and sash also plays a big part in the energy efficiency. In years gone by, windows were manufactured without and reinforcing, which left a large, cold cavity for heat to transfer through with relative ease. This was superseeded with steel or aluminium inserts in the frames, to allow the frames to be structurally stronger, but also offer an extra barrier against heat transfer and loss. As with all products, there are developments and advanced technology that enhances performance. In this instance, the reinforcing has developed and been replaced with 'thermal' reinforcing - or sometimes referred to as Recycled Composite Materials (RCM) inserts.

The thermal reinforcing offers a much warmer reinforcing material than steel or aluminium, which are notoriuosly cold products. The construction of the thermal reinforcing also offers two extra barriers to prevent against heat transfer/loss. It is also a greener product as the RCM material is made up of recycled window frames - that keeps a lot of people happy too!

The actual profile (a length of PVC pre manufcature) has also seen great developments. We now manufacture with a 'multi chamber' profile that offers great defense against heat transfer as each 'chamber' is another surface that the heat has to cross before being lost. The frames have also seen a change in depth over the years. Historically, 50mm or 60mm products have been manufactured. We now use 70mm products that again offer a larger surface for the heat to travel - ultimately reducing heat loss.